CUSTOMIZED

AUTOMATION

EQUIPMENT

With over 35 years of automation expertise, INO helps you automate and optimize production beyond screen printing.

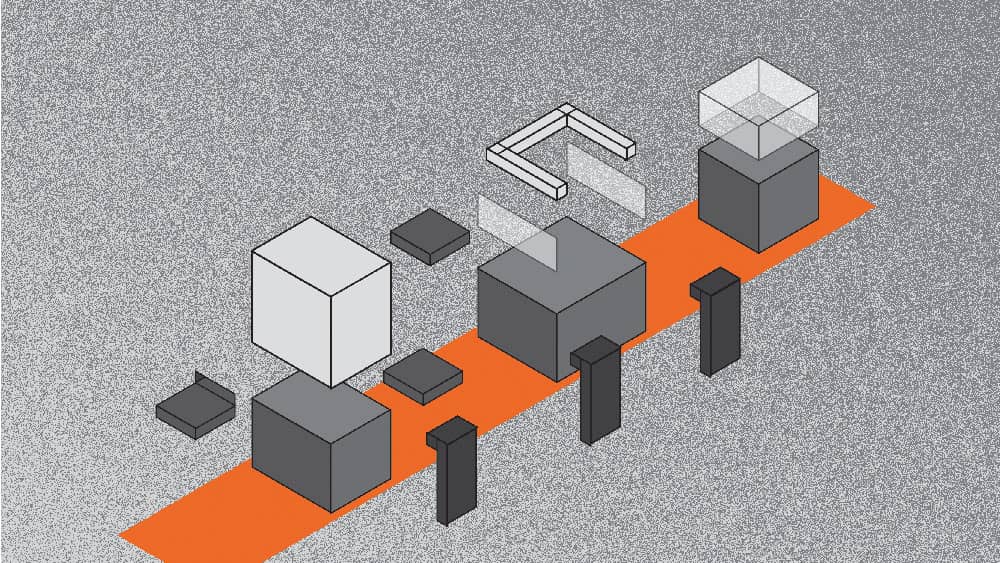

Automation Projects We’ve Delivered

- Automatic assembly lines

- Partially automated workplaces

- Mechanical, electrical, or optical final inspection machines

- Pre- and post-processing automation

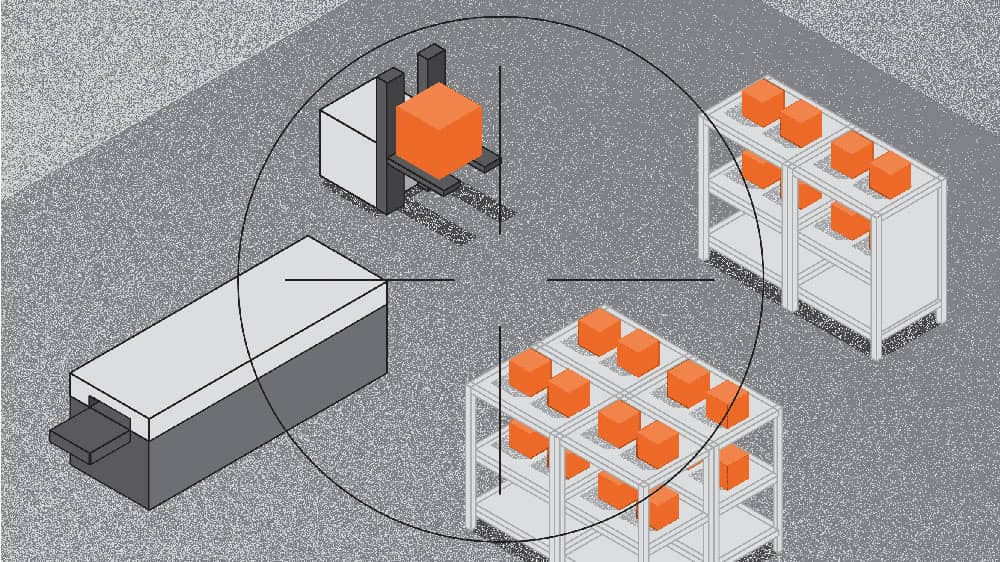

- Pick and place systems

- Lamination and die-cutting units

- Sorting and stacking solutions

- Electronic component integration

- Inline quality inspection and measurement systems

Showcasing Our Automation Expertise

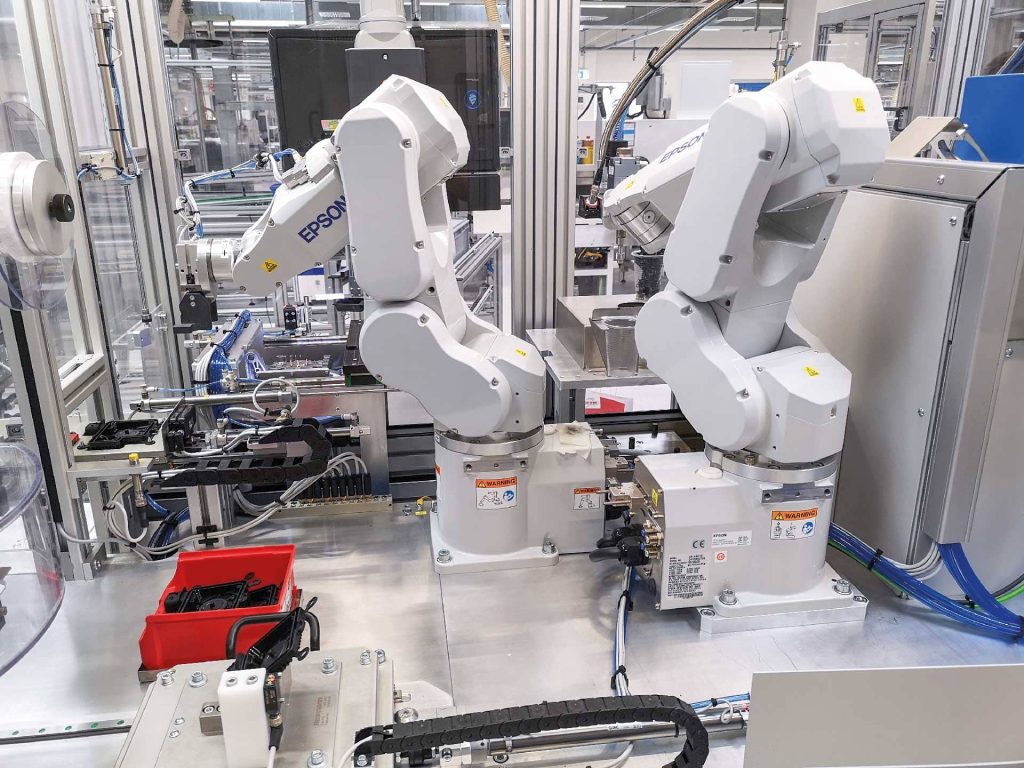

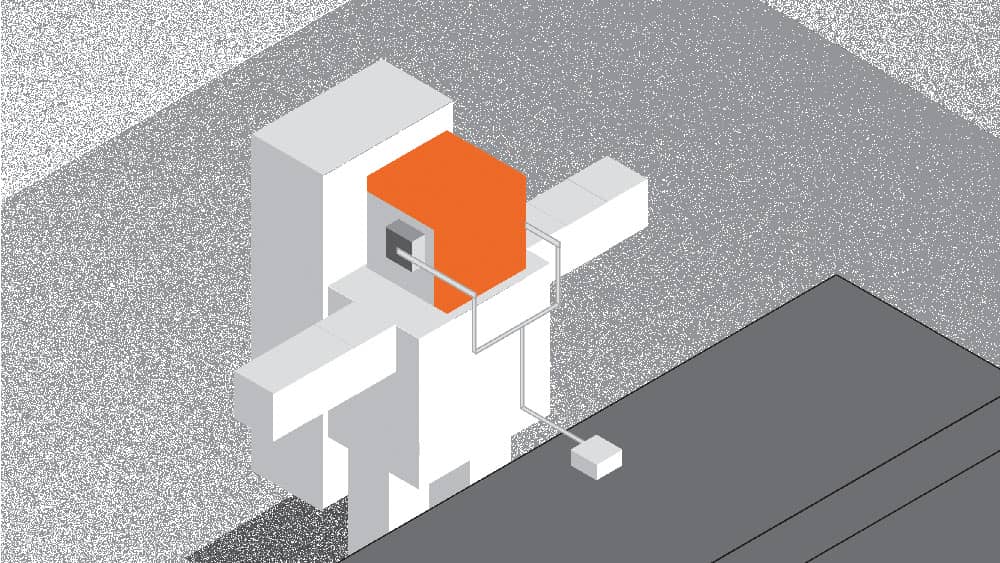

Rotor assembly production cell engineered to handle more than 100 different product types.

The robotic arm moves parts through a sequence of precise operations, including:

- Mechanical pressing

- Laser engraving

- Controlled glue dispensing

- Accelerator spray application

- Optical quality control

Tailored Solutions from Concept to Execution

Identifying Critical Operations

We analyze your production flow to identify tolerances and evaluate optimization opportunities from design and engineering perspectives.

Concept Development and Feasibility Testing

Early-stage planning is key. With 3D simulations, we visualize solutions, assess equipment compatibility, optimize cycle times, and ensure seamless integration. We validate concepts together before any investment.

Engineering, Manufacturing, and Programming

Our skilled team of engineers, assembly experts, and programmers—supported by scientists and specialists—brings your concepts to life entirely in-house with full process and quality control.

Testing and Fine-Tuning

We test the system comprehensively with your materials to ensure it meets your expectations. Regular on-site or remote reviews maintain transparency and alignment.

Installation, Training, and System Integration

Our streamlined on-site installation minimizes downtime. We provide comprehensive operator training, ensuring smooth adoption with clear operation, maintenance, and troubleshooting guidelines.

Global After-Sales Support

We stand behind our products. Our technical support team is available worldwide for remote diagnostics and assistance.

Identifying Critical Operations

We analyze your production flow to identify tolerances and evaluate optimization opportunities from design and engineering perspectives.

Concept Development and Feasibility Testing

Early-stage planning is key. With 3D simulations, we visualize solutions, assess equipment compatibility, optimize cycle times, and ensure seamless integration. We validate concepts together before any investment.

Engineering, Manufacturing, and Programming

Our skilled team of engineers, assembly experts, and programmers—supported by scientists and specialists—brings your concepts to life entirely in-house with full process and quality control.

Testing and Fine-Tuning

We test the system comprehensively with your materials to ensure it meets your expectations. Regular on-site or remote reviews maintain transparency and alignment.

Installation, Training, and System Integration

Our streamlined on-site installation minimizes downtime. We provide comprehensive operator training, ensuring smooth adoption with clear operation, maintenance, and troubleshooting guidelines.

Global After-Sales Support

We stand behind our products. Our technical support team is available worldwide for remote diagnostics and assistance.

Looking to Automate Your Production?

Our engineers are available to discuss your process needs and suggest tailored automation solutions based on your technical specifications.