Minimized Scratch

- Anti-scratch substrate manipulation.

- Optimized for thin materials.

- Camera-controlled print auto-registration to the sheet edge or image target (previous print)

- Auto-print length correction

- Quick Fit—automatic positioning during screen changeover

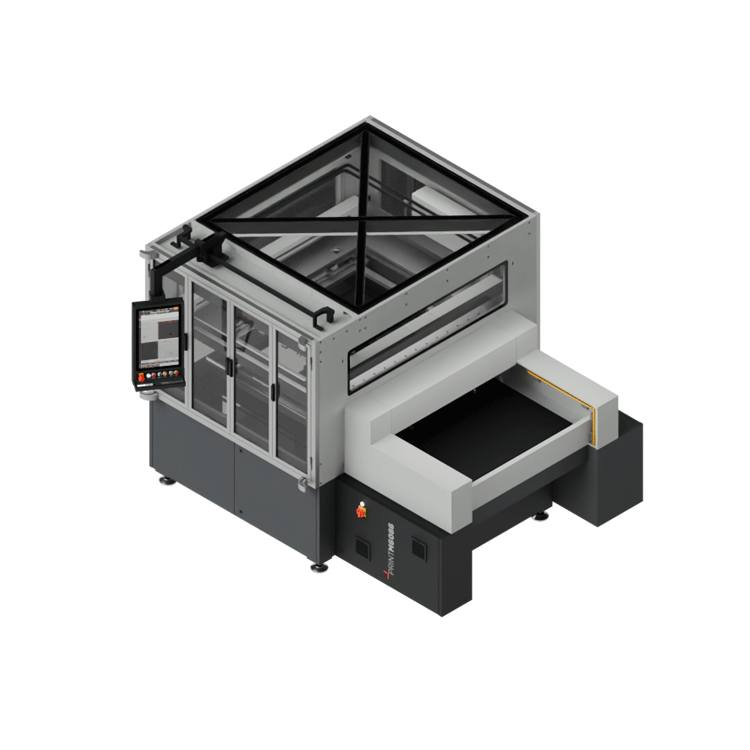

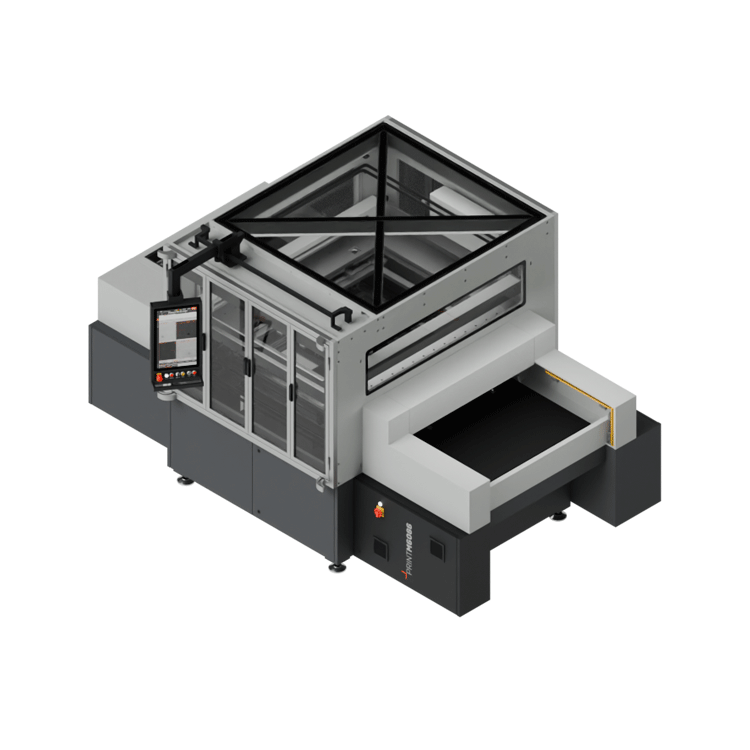

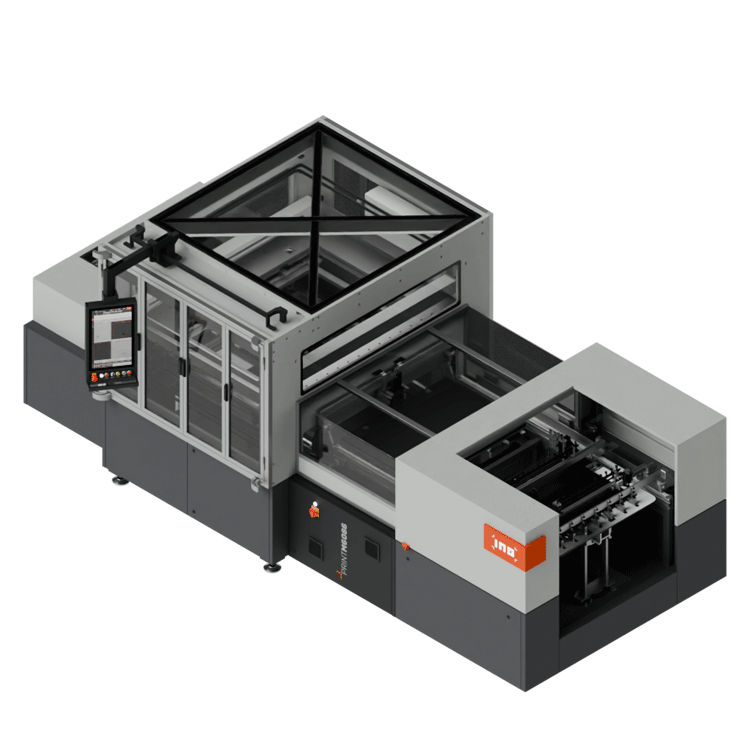

- Modular design for easy upgrades

- Full integration with DRY and STACK

- Intuitive software and HMI logic

- Enhanced anti-static kit: discharge electrode on squeegee bridge and ionized air gun

- Pneumatic RKS squeegee holder

- Front and back doors on protective housing

- Production data protocol—Industry 4.0