INO PE Line M

Modular Printed Electronics Line for Sensitive Materials

The INO PE Line M is designed for precision printing on thin, delicate substrates. It combines anti-scratch handling, high accuracy, and modular flexibility, enabling a smooth transition from R&D to scalable production—ideal for prototyping, validation, and scalable manufacturing.

INDUSTRY

PRODUCTS

Scratch-Free Production

Even minor surface damage can compromise sensitive materials.

Line’s advanced transport and cleaning systems ensure defect-free handling from printing to stacking.

Precision and Repeatability

Auto-registration, print length correction, and advanced controls deliver consistent high-accuracy output even at micro tolerances.

Modular, Upgradable Design

Scaling from prototype to production can be challenging due to inconsistent repeatability and high costs. INO’s modular platform preserves settings, reduces cost, and accelerates the shift to full-scale manufacturing.

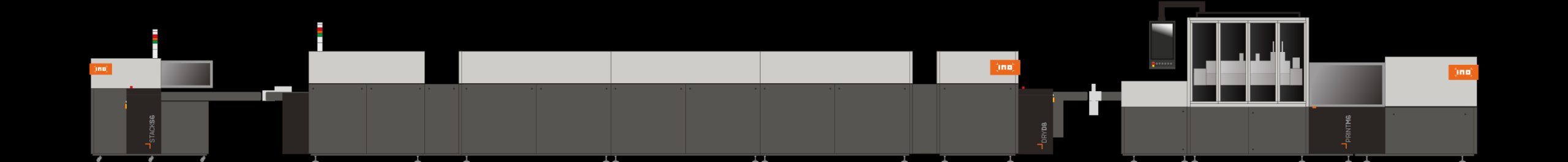

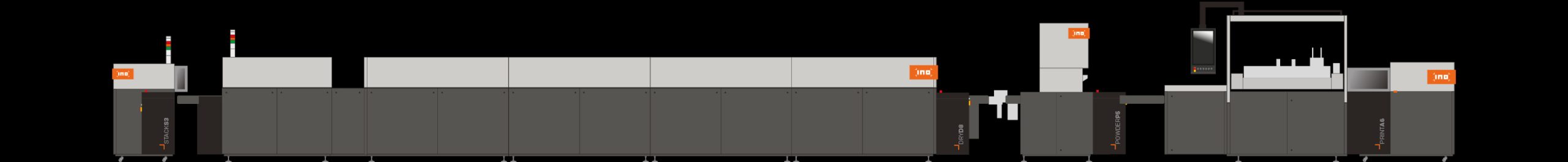

INO PE Line A

High-Volume Printed Electronics Line

The INO PE LINE is made for large-scale production of printed electronic components.

Combining high-speed performance with consistent print quality, it offers seamless integration with smart factory systems, helping manufacturers reduce material use and optimize workflows for high-tech industries, ideal for automotive, consumer electronics, healthcare, and more.

INDUSTRY

PRODUCTS

Minimizing Waste, Maximizing Sustainability

High material costs and setup waste increase expenses. The A7’s automatic screen positioning cuts waste to a few sheets per job, lowering costs and boosting sustainability.

Reliable Drying Across Materials

Integration with Smart Factory Systems

Disconnected real-time data hinders manufacturing and decision-making. Industry 4.0 connectivity enables seamless integration with production management systems for smarter operations.

INO HT Line A

High-Volume Heat Transfer Line

The INO HT LINE is designed for industrial-scale textile heat transfer production.

It combines the durability of screen printing with the flexibility of digital printing, enabling manufacturers to deliver higher-quality products quickly to meet market demands.

INDUSTRY

PRODUCTS

Balancing Quality and Cost

High-quality production must stay cost-effective.

The INO HT Line automates critical steps, cuts setup time and waste, and boosts output per shift—lowering cost per transfer while improving print quality.

Enabling Personalization at Scale

Orders can range from large batches to fully customized jobs.

Switch effortlessly between long and short runs with easy setups and quick screen changeovers—whether using standard screen printing or hybrid production modes.

Simplified Operation

Skilled screen printers are becoming scarce. This line ensures consistent, high-quality output with minimal operator input—thanks to automation, recipe-based workflows, and built-in precision systems.

INO Line V6

3/4 automatic screen printing machine for various substrates

INDUSTRY

PRODUCTS

Our specialists will prepare a tailored analysis of your savings and return on investment.